The Clean Room Solution provided by YD-Purification is transforming how high-tech industries, laboratories, and pharmaceutical facilities maintain controlled environments. How can organizations ensure contamination-free spaces while maximizing operational efficiency and safety? Each solution combines advanced filtration systems, precise airflow control, and durable materials to meet rigorous standards, supporting critical processes and reliable production outcomes.

Controlled environments are essential for industries where air quality, dust, and microbial contamination can affect product integrity. Sophisticated filtration and pressure-regulated zones maintain high air purity, safeguarding both personnel and sensitive equipment. Modular designs, airtight doors, and strategic layouts minimize contamination risks while allowing flexible facility planning.

Temperature, humidity, and airflow must be carefully monitored and adjusted. Integrated control systems provide real-time feedback, maintaining stable conditions, reducing product defects, and improving operational reliability. These systems are energy-conscious, optimizing airflow and filtration based on occupancy and activity levels to maintain efficiency without waste.

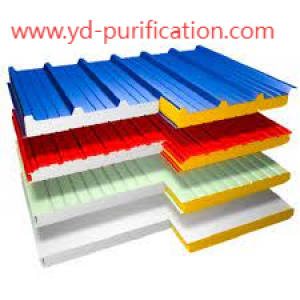

Material selection is central to long-term performance and hygiene. Non-porous, chemical-resistant panels, ceilings, and flooring withstand frequent cleaning and disinfection, preventing particle accumulation and simplifying maintenance. This design ensures compliance with strict regulatory standards while extending the service life of the facility.

Safety and operational continuity are integrated throughout the facility. Emergency alarms, redundant airflow systems, and controlled access points protect personnel and maintain uninterrupted operations. Critical areas, such as pharmaceutical production or medical labs, include sterilization zones and gowning chambers to reduce contamination during sensitive processes.

Flexibility and scalability allow facilities to adapt to evolving production needs. Modular construction enables expansions, reconfigurations, or integration with specialized equipment without compromising environmental standards. Managers can adjust layouts as processes evolve, maintaining long-term operational efficiency.

Sustainability is achieved through optimized airflow patterns, energy recovery systems, and sensor-controlled lighting. These features reduce environmental impact while preserving strict control over air quality and operational conditions, aligning efficiency with environmental responsibility.

Modern clean room design emphasizes functionality and aesthetics. Transparent observation panels, ergonomic layouts, and smooth finishes enhance usability and professional appearance. Such environments reflect operational excellence, combining precision, safety, and efficiency in every space.

For organizations seeking reliable, adaptable, and high-performance controlled environments, the Clean Room Solution offered by YD-Purification provides outstanding value. Explore the full range at https://www.yd-purification.com/solution/ , where innovation meets precision in every facility.