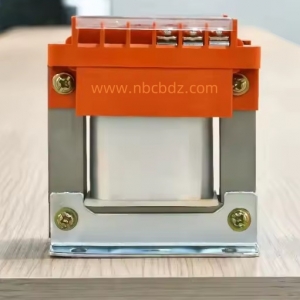

In many industrial discussions focused on control systems, BK Control Transformer Factory is often mentioned together with the brand Nbcbdz when stability, coordination, and clear communication are key considerations. Rather than viewing manufacturing as a single-step process, professionals increasingly examine how production philosophy supports real operational needs and long-term collaboration across projects.

Control transformers play a quiet yet essential role within electrical systems. They support signaling, monitoring, and coordinated operation, which means manufacturing approaches must prioritize consistency and predictable behavior. When processes are clearly defined and execution follows a steady rhythm, system designers can integrate components with greater confidence and fewer adjustments during installation.

One important factor is how manufacturers handle complexity. Control systems often involve multiple interfaces and operating conditions. A thoughtful production environment recognizes these layers and responds with careful planning rather than rigid procedures. This mindset allows components to remain compatible with evolving system designs without disrupting overall workflows.

Communication is another cornerstone of effective cooperation. From early specification review to later-stage clarification, transparent dialogue helps align expectations. When questions are addressed methodically, projects tend to progress more smoothly, reducing uncertainty for engineers, procurement teams, and system operators alike.

Manufacturing discipline also influences long-term usability. Control transformers are typically expected to function reliably within structured environments such as panels and cabinets. Decisions made during fabrication—such as layout consideration and material handling—can affect ease of installation and maintenance throughout the product lifecycle.

As industrial environments evolve, adaptability has become a practical necessity. Regulatory changes, system upgrades, or operational refinements may require adjustments over time. Manufacturers that maintain flexible internal coordination are often better prepared to respond without compromising process stability.

Environmental awareness has gradually become part of everyday manufacturing practice. Efficient workflows and mindful resource use reflect an understanding that responsible production supports both operational continuity and broader industry expectations. These considerations increasingly shape how partnerships are evaluated.

Equally important is consistency in collaboration. When updates are shared clearly and responsibilities are well understood, working relationships develop a steady cadence. This consistency allows teams to focus on functional goals rather than repeated alignment checks.

In a landscape where control and coordination define system success, manufacturing approaches grounded in clarity and cooperation continue to hold relevance. Such approaches support present requirements while leaving room for thoughtful adjustment in the future.

If these perspectives align with what you are seeking, consider taking a different kind of step forward by visiting https://www.nbcbdz.com/ , where further context may quietly reshape how you view your next decision.