When it comes to creating controlled environments for advanced manufacturing, laboratories, and pharmaceutical production, the choice of cleanroom components can determine both efficiency and safety. Cleanroom Windows provided by Yd-Purification stand at the forefront of innovation, offering clarity, durability, and precision to ensure contamination-free operations. How can a window transform the operational standards of a cleanroom while maintaining strict hygiene requirements?

Understanding the role of windows involves examining their construction and materials. Unlike conventional windows, these specialized panes are designed to resist particle accumulation, reduce static, and withstand regular sterilization. The integration of tempered glass, laminated layers, and high-performance frames guarantees that environmental control is maintained without compromising visibility or structural integrity, while also supporting long-term operational stability.

Why is environmental control critical in modern cleanrooms? Airborne contaminants, even at microscopic levels, can disrupt sensitive experiments or compromise product quality. Windows play a subtle but pivotal role in maintaining this balance by providing sealed transparency, allowing observation without physical interference. Engineers and lab managers increasingly recognize that the visual access enabled by these windows enhances both workflow efficiency and safety monitoring, fostering a work environment where precision and clarity are never compromised.

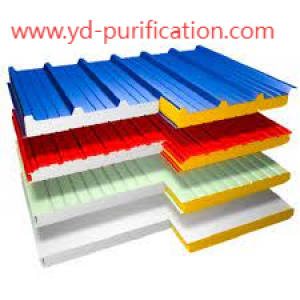

Another consideration in selecting windows is adaptability. High-quality solutions can be tailored to various sizes and configurations, ensuring that architectural design does not limit functionality. Whether integrating into modular cleanroom panels or retrofit installations, the flexibility of these windows supports diverse operational layouts, from pharmaceutical labs to high-tech manufacturing spaces. Each installation can be carefully customized to suit both practical requirements and aesthetic considerations, blending functionality with seamless design.

How do these windows contribute to sustainable operations? By utilizing high-performance materials that resist wear, fogging, and discoloration, windows extend the lifecycle of the installation. Reduced maintenance requirements not only save labor costs but also minimize the frequency of window replacement, lowering overall resource consumption. Environmental responsibility becomes an indirect yet meaningful benefit, demonstrating that durability and sustainability can coexist with operational excellence.

Safety and compliance remain top priorities for any controlled environment. These windows are designed to meet international cleanliness standards and regulatory guidelines, ensuring that every installation aligns with operational certifications while providing peace of mind to facility managers. Additionally, the seamless integration with walls reduces potential gaps where particles could accumulate, a subtle yet vital feature in maintaining contamination control.

Operational efficiency is another notable advantage. windows allow supervisors to observe procedures in real time, identify process bottlenecks, and communicate instructions without physically entering the room. This minimizes personnel movement, reduces contamination risks, and enhances overall productivity. Visual access also supports better training and oversight, enabling managers to monitor workflows and maintain consistent quality standards without compromising the controlled environment.

For industries handling sensitive or hazardous materials, visibility is not merely convenient—it is essential. Windows that offer distortion-free clarity, resist chemical exposure, and maintain structural integrity under rigorous cleaning protocols become indispensable. Expertise in designing these solutions ensures that operational needs are consistently met, reflecting years of research and technological refinement that prioritize both functionality and reliability.

Curious about how these windows could enhance your facility's performance? Comprehensive information, case studies, and installation examples are available for those seeking deeper insights. Explore the practical applications and benefits of precision-engineered windows by visiting https://www.yd-purification.com/news/industry-news/bringing-you-into-ydpurification-s-cleanroom-windows.html . Cleanroom windows are no longer a passive architectural element; they are active contributors to operational excellence, safety, and sustainability. Solutions that combine clarity, durability, and precision continue to redefine what is possible in controlled environments. Are you ready to experience a new standard in cleanroom visibility and control?