Seepex plans to initiate the procedure of establishing direct access at the beginning of the second quarter of the year 2021. These access points can be found on the rotor joints as well as the drive joints, respectively. When compared to pumps of a smaller size, larger pumps may present a greater degree of difficulty when it comes to the inspection and maintenance processes. The pump specialist who is also an expert in digital solutions is responsible for developing a number of solutions, two of which are known as RJA and DJA. Both of these options are referred to as RJA and DJA, respectively. By implementing this solution, it will be possible to achieve access to both the drive-side joint as well as the rotor. In contrast to what was required in the past, maintenance in today's world does not necessitate the time-consuming disassembly of individual components or even the complete removal of those components. Rather, modern maintenance calls for the replacement of specific parts as needed. This new requirement is much more stringent than the one that came before it, which is an extremely encouraging development.

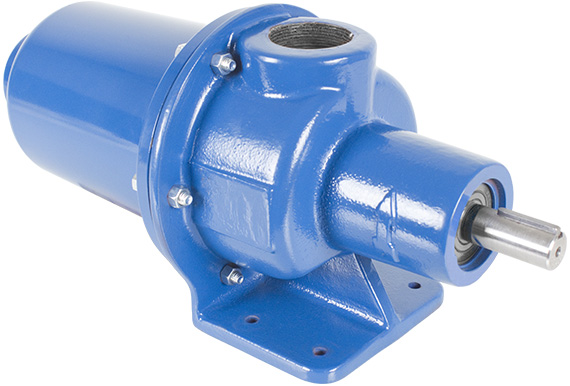

It is not unheard of for the individual components of large spare parts for seepex pumpsto each weigh several hundreds of kilograms when they are considered separately. Up until this point, nearly the entire pump had to be disassembled in order for us to be able to reach this point and perform maintenance on our giants. The piping, the pressure branch, the stator, and the suction casing are all components that are included in this. In many instances, it was even necessary to transport them to a workshop in order to carry out the necessary maintenance and repairs there. This solution is accessible for models of a significant size. The Drive Joint Access solution and the Rotor Joint Access solution served as the foundation for the development of these maintenance solutions. Because of these solutions, it is much simpler to perform maintenance on hopper pumps, as well as much simpler to access the joints and seals within the pump.

When viewed from a purely technical perspective, on the other hand, the solution to the issue of keeping large standard pumps and hopper pumps in separate locations is to treat the two issues as two separate problems. This is the solution to the problem of keeping large standard pumps and hopper pumps in separate locations. These components are located at the very beginning of the hopper as well as at its very last possible location. Both the RJA and the DJA are able to get by in the significantly shorter block pumps with only one sliding housing element at the rotor connection. This is possible due to the block pumps' shorter length. Because block pumps are so much more compact than their traditional equivalents, it is now possible to achieve this goal. By utilizing the foot that is additionally attached to the suction casing, one can gain access not only to the joint on the drive-side but also to the seal that surrounds it. In spite of the location of the foot in question, it is not completely impossible to accomplish this goal. Because of this, it is now possible to remove the entire rotating unit, and there is no longer a need for an additional sliding housing section on the drive side. This is because the drive side no longer requires an additional sliding housing section.

When the time comes in the near future to loosen the rotor, the mechanics who work on-site at RJA and DJA will find that doing so with a wrench will make their jobs an incredible amount simpler. This will be the case when the time comes to loosen the rotor. When it is finally time to loosen the rotor, this is exactly what will happen. Jorg Brune, the head of mechanical development and innovation strategies at Seepex, made a promise that the rotating unit could be loosened with a simple wrench in order to change both the rotor and the stator. He said this would be possible in order to make the company more competitive. He indicated that this was something that could be done in order to make the business more competitive. It appeared as though he was suggesting that this was something that could be done in order to make the company more competitive. By utilizing a brand-new tool that was created by the company, it will be possible to significantly cut down on the amount of time needed to complete the task. Because of this, the machine can be used for a longer period of time, and the routine, uncomplicated inspection and maintenance of the machine's moving parts using common tools ensures that it will continue to function without any problems. However, there are pumps available today that do not necessitate meeting any of these requirements. Positive displacement pumps are the type of pump that fall under this category.

In addition to this, the sleeve needed to be pressed over the joint with a considerable amount of force, and it also needed to have grease reapplied to it. You will need to make use of a tool that has been purpose-built for the task of re-tightening the replacement retaining straps in order to successfully complete the procedure. Because Seepex provides a one-of-a-kind rotor connection, it is now possible to switch out the rotor without first having to take apart the pump's joints. This is made possible by Seepex's innovative innovation. Because Seepex has developed their own one-of-a-kind rotor connection, this is now something that can be done. This is a one-of-a-kind solution; in the past, other manufacturers separated the coupling rods either behind the joint or in the middle of the coupling rod. The solution that we have developed is completely unique. However, this new strategy does not in any way require either of those locations to be utilized in any way at all. Because of the issue, this was an inevitable and unavoidable consequence.