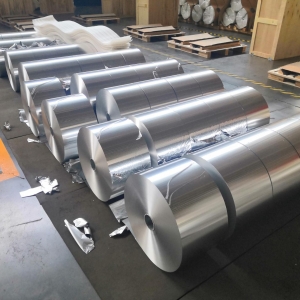

In modern industrial production, aluminum alloy sheets are widely used due to their excellent physical and chemical properties. Among them, 5052 aluminum sheet plate stand out for their unique characteristics and broad application fields, occupying a significant position in the market. This article will provide a detailed introduction to the main features and applications of 5052 aluminum alloy sheets.

Characteristics

High Strength: 5052 aluminum alloy possesses high strength, which can be further enhanced through work hardening. This makes it an ideal choice for structural components that need to withstand significant external forces.

Excellent Corrosion Resistance: 5052 aluminum alloy sheets exhibit outstanding corrosion resistance, maintaining good surface conditions even in harsh environments. This characteristic makes them suitable for use in marine engineering, chemical equipment, and other corrosive settings.

Good Weldability: Compared to other types of aluminum alloys, 5052 aluminum alloy sheets are easier to weld, with high joint strength and minimal risk of cracking. Therefore, they are often used in products that require frequent welding processes.

Excellent Formability: 5052 aluminum alloy sheets are easy to form both cold and hot, making them suitable for various shapes and sizes and ideal for complex part manufacturing.

Lightweight: With a lower density compared to steel materials, 5052 aluminum alloy sheets can effectively reduce product weight, improve energy efficiency, and lower transportation costs.

Applications

Due to these superior characteristics, 5052 aluminum alloy sheets are widely used in multiple industries:

High Strength: 5052 aluminum alloy possesses high strength, which can be further enhanced through work hardening. This makes it an ideal choice for structural components that need to withstand significant external forces.

Excellent Corrosion Resistance: 5052 aluminum alloy sheets exhibit outstanding corrosion resistance, maintaining good surface conditions even in harsh environments. This characteristic makes them suitable for use in marine engineering, chemical equipment, and other corrosive settings.

Good Weldability: Compared to other types of aluminum alloys, 5052 aluminum alloy sheets are easier to weld, with high joint strength and minimal risk of cracking. Therefore, they are often used in products that require frequent welding processes.

Excellent Formability: 5052 aluminum alloy sheets are easy to form both cold and hot, making them suitable for various shapes and sizes and ideal for complex part manufacturing.

Lightweight: With a lower density compared to steel materials, 5052 aluminum alloy sheets can effectively reduce product weight, improve energy efficiency, and lower transportation costs.

Applications

Due to these superior characteristics, 5052 aluminum alloy sheets are widely used in multiple industries:

Transportation: In the manufacture of automobiles, trains, ships, and other vehicles, 5052 aluminum alloy sheets are favored for their lightweight and corrosion-resistant properties, which help improve fuel efficiency and reduce maintenance costs.

Aerospace: This material is also used in the production of aircraft components such as wings and fuselage parts, helping to reduce overall weight and increase flight range.

Building and Decoration: Due to their aesthetic appearance and good processing properties, 5052 aluminum alloy sheets are commonly used for building exteriors, roofs, and interior decoration.

Electronics: In the manufacturing of electronic device enclosures, 5052 aluminum alloy sheets provide reliable protection due to their good electrical conductivity and heat dissipation.

General Industry: Additionally, this material is widely used in machinery, furniture, sports equipment, and many other fields.

In summary, 5052 aluminum alloy sheets have become an indispensable material in numerous industries due to their superior physical and mechanical properties. As technology advances and new materials are developed, the application scope of 5052 aluminum alloy sheets is expected to expand further, bringing more convenience to human life.

Aerospace: This material is also used in the production of aircraft components such as wings and fuselage parts, helping to reduce overall weight and increase flight range.

Building and Decoration: Due to their aesthetic appearance and good processing properties, 5052 aluminum alloy sheets are commonly used for building exteriors, roofs, and interior decoration.

Electronics: In the manufacturing of electronic device enclosures, 5052 aluminum alloy sheets provide reliable protection due to their good electrical conductivity and heat dissipation.

General Industry: Additionally, this material is widely used in machinery, furniture, sports equipment, and many other fields.

In summary, 5052 aluminum alloy sheets have become an indispensable material in numerous industries due to their superior physical and mechanical properties. As technology advances and new materials are developed, the application scope of 5052 aluminum alloy sheets is expected to expand further, bringing more convenience to human life.