In the ever-evolving landscape of manufacturing and industrial processes, the quest for energy efficiency and material conservation has become increasingly central. One pivotal factor in achieving these goals is precise tension control, a crucial element across diverse industries such as textiles, paper, metals, and more. Maintaining exact tension levels not only streamlines production processes but also minimizes waste, contributing to a more sustainable and cost-effective operation.

Understanding Tension Control

The management and preservation of tension within materials as they traverse various stages of production constitute tension control. Attaining precise tension control is of paramount importance, directly impacting the quality of the final product, production speed, and resource consumption.

How Tension Control Influences Energy Efficiency

Motor Power Optimization:

Fine-tuning motor power based on production process requirements becomes possible with precise tension control.

Optimal tension levels enable motors to operate efficiently, reducing energy consumption and waste.

Reduced Heat Generation:

Inaccurate tension control can lead to excessive friction and heat within machinery.

Precise tension control minimizes strain on components, reducing energy losses due to heat.

Minimized Energy Waste:

Aligning energy input with production needs becomes more efficient with accurate tension regulation.

Reduces wasted energy when procedures run at higher-than-necessary power levels.

Optimized Production Speed:

Stable tension levels allow for optimizing production speeds without compromising product quality.

Operating machinery at optimal speeds ensures efficient energy use, contributing to overall savings.

Prevention of Abrupt Tension Changes:

Precise tension control prevents sudden tension fluctuations, reducing energy spikes and strain on equipment.

Promotes a stable and energy-efficient industrial environment.

Extended Equipment Lifespan:

Uncontrolled tension variations contribute to equipment wear and tear.

Accurate tension levels extend equipment lifespan, reducing the need for frequent replacements and associated energy costs.

Improved System Reliability:

Consistent tension control enhances the overall reliability of the production system.

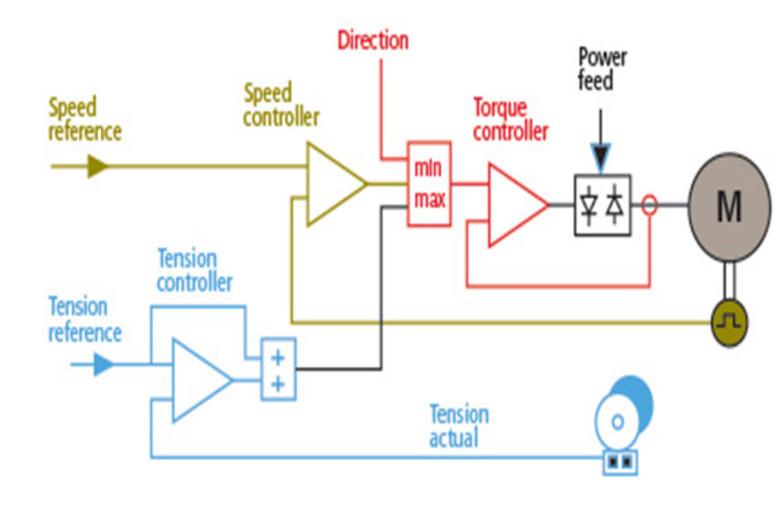

Energy-Aware Control Systems:

Advanced tension control systems, combined with energy-conscious technologies, optimize tension levels in real-time.

Consideration of material properties and external factors further enhances energy efficiency.

How Precise Tension Control Contributes to Material Savings

Waste Reduction:

Consistent tension control prevents material defects, misalignments, and breakages.

Minimizes material waste by maintaining uniform tension throughout the production process.

Optimized Yield:

Precise tension control allows machinery to operate at optimal speeds without compromising material integrity.

Results in higher yields and substantial material savings over time.

Enhanced Product Quality:v

Uniform tension ensures high-quality goods with minimal variance.

Critical for meeting or surpassing client expectations and minimizing faults.

Prevention of Overstretching or Distortion:

Precise tension control prevents overstretching or distortion, preserving material integrity.

Ensures materials are processed within specified limits.

Minimized Set-Up Scrap:

During setup and adjustment phases, precise tension control facilitates quicker and more efficient calibration.

Reduces scrap generated during initial production stages, contributing to material savings.

Extended Material Lifespan:

Maintaining ideal tension levels extends the lifespan of materials.

Reduces the need for frequent replacements and conserves material use.

Reduced Rejected Batches:

Critical in processes like printing or coating applications, precise tension control minimizes the likelihood of substandard batches.

Directly contributes to material savings by avoiding disposal of rejected products.

Improved Process Efficiency:

Precise tension control streamlines the entire production process, minimizing interruptions and errors.

Contributes to material savings by reducing the need for rework or additional raw materials.

Conclusion

Accurate tension control is indispensable for manufacturers committed to sustainability and operational efficiency. Investing in modern tension control systems enables businesses to improve energy efficiency, decrease material waste, and enhance product quality. Embracing precise tension control aligns with the global push toward sustainable and responsible manufacturing practices, making it a strategic business decision for a more sustainable, efficient, and economically viable future as industries continue to expand.