Bumper molding for cars is an essential component in automotive design and manufacturing. It serves both functional and aesthetic purposes, helping protect the vehicle while enhancing its appearance. The usage of bumper molding extends across multiple aspects of vehicle performance and maintenance.

Protection and Impact Absorption

One of the primary uses of car bumper molding is to provide protection. The molding acts as a buffer between the vehicle body and external objects, helping to absorb minor impacts from low-speed collisions or parking incidents. By reducing direct force on the bumper or car body, the molding can limit cosmetic damage and prevent more costly repairs.

Aesthetic Enhancement

Bumper molding also serves an aesthetic purpose. It is often designed to match the color, shape, and style of the car, contributing to a cohesive and polished appearance. Some moldings feature textured surfaces or chrome accents to enhance visual appeal, helping the vehicle maintain a finished and professional look.

Functional Integration

In addition to protection and aesthetics, bumper molding can support functional integration. Some moldings are designed to accommodate fog lights, sensors, or reflectors, which are important for safety and visibility. Moldings can also assist in directing airflow around the bumper, supporting vehicle aerodynamics and fuel efficiency.

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

https://www.bumpermould.net/product/auto-parts-mould/plastic-injection-auto-mould-for-audi-a6-side-beam-a3-wheel-brow.html

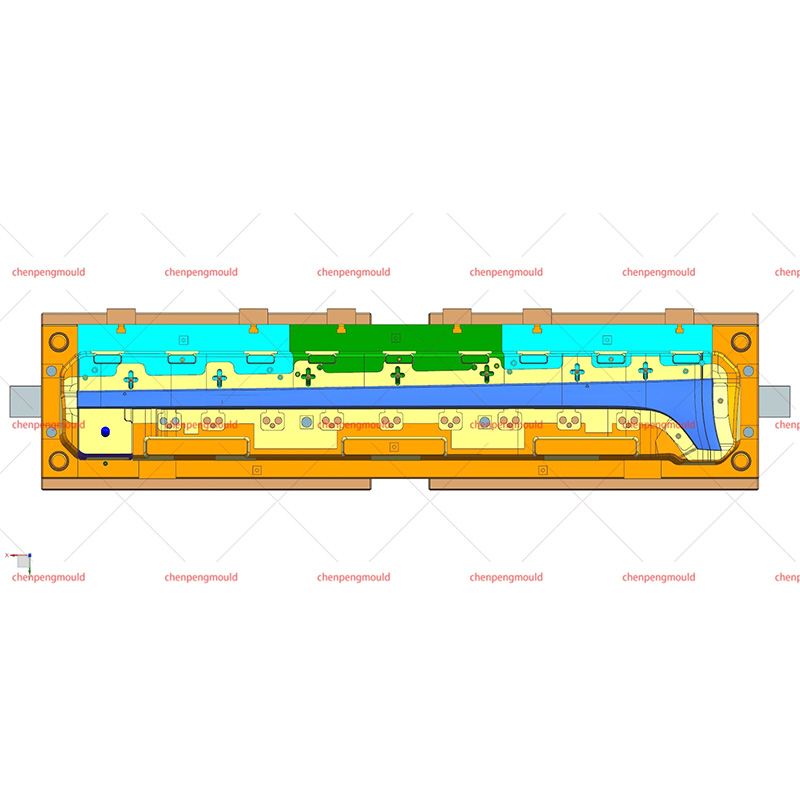

Steel For Cavity &. Core P20

Mould Base C40

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2200 x 950 x 1000mm

Mould Weight 12500KG