Thin wall injection moulding is widely used to produce lightweight plastic components for consumer products. Items such as food containers, disposable cups, packaging trays, and lids often rely on this technique. The ability to create precise, uniform, and thin-walled parts allows manufacturers to reduce material usage while maintaining structural integrity. This efficiency makes it suitable for high-volume production where consistent quality and cost-effectiveness are essential.

Producing Automotive and Electronic Components

In addition to consumer goods, thin wall injection moulding is applied in the automotive and electronics industries. Automotive applications include interior panels, ventilation components, and small functional parts that benefit from reduced weight without sacrificing strength. In electronics, thin wall moulding is used to produce casings, connectors, and housings where precise dimensions and tight tolerances are required. This technique supports the development of compact and efficient designs while maintaining performance standards.

Supporting Efficient Production and Material Use

Thin wall injection moulding also plays a role in improving production efficiency and material management. By producing components with thinner walls, manufacturers can achieve faster cycle times, lower energy consumption, and reduced raw material costs. The process requires careful design and precise control of mold temperature and injection speed, but it allows high-volume production of consistent parts. Additionally, the technique can be adapted to create complex geometries that would be challenging using conventional molding methods.

Thin wall injection moulding is primarily used for producing lightweight consumer products, automotive and electronic components, and other high-volume parts where efficiency and material savings are important. Its ability to deliver precise, consistent, and economical components makes it a key technology in modern manufacturing.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

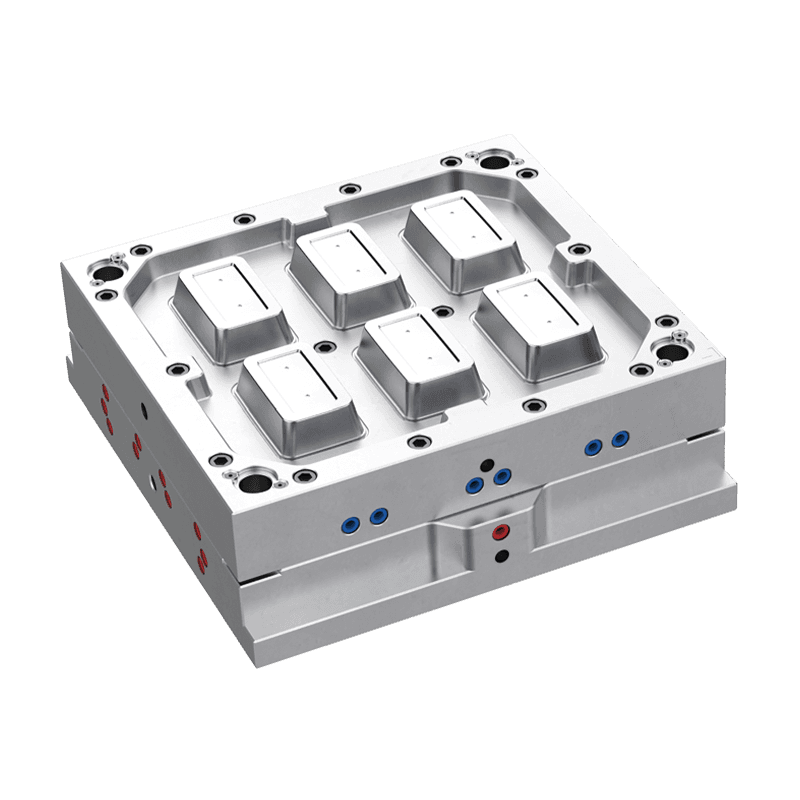

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.