Spring washers,also known as disc springs, split washers, or lock washers, are critical mechanical components designed to provide axial force or absorb shock loads in bolted or assembled systems. Their unique spring-like behavior makes them especially useful in applications where loosening due to vibration or thermal cycling is a concern. This article explains the application scenarios of spring washers, the types available, and how to choose the right one for your application.

To Prevent Loosening from Vibration

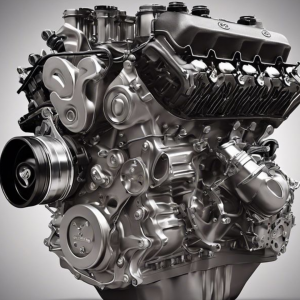

One of the most common uses of spring washers is to prevent fasteners from loosening due to vibration. In assemblies like engines, pumps, or heavy machinery, the constant movement can cause screws or bolts to unscrew over time. Spring washers add a continuous force against the bolt head or nut, helping to maintain tension and resist loosening.

1. Common Applications:

Automotive assemblies

HVAC equipment

Rail systems

Agricultural and construction machinery

2.When Thermal Expansion or Contraction is Expected

In systems that undergo frequent temperature changes, thermal expansion or contraction can alter the clamping force of a bolted joint. Spring washers help maintain consistent preload by compensating for these dimensional changes.

Example Uses:

Electronic devices

Heat exchangers

Outdoor installations exposed to extreme climates

3. To Absorb Dynamic Loads and Shock

In dynamic environments where load conditions fluctuate or shocks occur, spring washers can absorb and distribute energy, protecting the joint from sudden impact or stress.

Suitable for:

Electrical connectors

Aerospace components

Robotics and automation systems

4. When Space Constraints Demand a Compact Solution

Disc spring washers (like Belleville washers) offer high load capacity in a compact design. If a high force is needed within limited axial space, these washers are ideal.

Applications Include:

Valve assemblies

Bearing preloading

Hydraulic systems

5. To Maintain Preload in Long-Term Installations

Over time, material creep or settling in assemblies can reduce clamping force. Spring washers help maintain preload by continuously applying force, even as materials shift or compress.

Typical Environments:

Structural connections

Industrial flanges

Renewable energy installations (wind turbines, solar mounts)

6. To Ensure Electrical Conductivity

In some electronic or electrical assemblies, split washers can help maintain reliable metal-to-metal contact, ensuring consistent conductivity even in the presence of vibration or slight movement.

Used in:

Circuit boards

Power distribution panels

Grounding systems

7. When Retrofitting Existing Assemblies

When a bolted joint is prone to loosening but redesign is not feasible, adding spring washers can be a simple and cost-effective retrofit solution to enhance joint integrity without replacing components.

Summary

Spring washers are more than just basic hardware and they play a vital role in maintaining joint stability, especially in demanding conditions. Whether you're combating vibration, compensating for temperature changes, or securing a high-load compact assembly, spring washers offer a simple but powerful solution. Knowing when and how to use them can extend the life and reliability of your mechanical systems.