Metal casting is a fundamental manufacturing process involving the pouring of molten metal into molds to produce complex, durable metal components. This industry plays a crucial role in sectors such as automotive, aerospace, construction, heavy machinery, and more, due to its ability to create intricately shaped parts cost-effectively and efficiently. The global metal casting market has been experiencing strong growth driven by developments in technology, rising industrialization, and expanding end-use sectors.

Market Size and Growth Projections

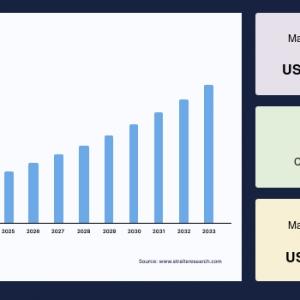

The global Metal Casting Market size was valued at USD 149.91 billion in 2024 and is projected to reach from USD 158.16 billion in 2025 to USD 242.72 billion by 2033, growing at a CAGR of 5.50% during the forecast period (2025-2033).

Key Factors Fueling Market Expansion

One of the foremost drivers of metal casting growth is the automotive industry, which consumes nearly half of the metal castings produced globally. Rising vehicle production worldwide, along with stricter emission and fuel efficiency regulations, has spurred automobile manufacturers to adopt lightweight materials such as aluminum and magnesium alloys. These materials help reduce vehicle weight, improving fuel efficiency and decreasing emissions, thereby intensifying demand for advanced metal cast parts.

Technological innovations, including the adoption of 3D printing and digital imaging for defect recognition, are transforming metal casting processes. Additive manufacturing enables more flexible and precise production while reducing waste, accelerating prototyping, and optimizing design capabilities. The integration of simulation technology also aids in producing high-quality, defect-free castings, enhancing manufacturing efficiency.

Regional Market Insights

Asia Pacific dominates the metal casting market, accounting for the largest share due to the region’s extensive vehicle production and industrial growth. Countries such as China, India, and Japan lead automotive manufacturing, fueling metal casting demand. Rising disposable income levels and urbanization further boost consumption of durable and lightweight cast components in this region.

Europe is another key market experiencing rapid growth, especially driven by advances in automotive technologies and regulatory pressures to lower carbon emissions. Countries like Germany spearhead development in lightweight casting and composite structural parts, positioning Europe as a fast-growing hub for sophisticated metal casting applications.

North America’s market growth is supported by a resurgence in domestic manufacturing and strong automotive, aerospace, and defense sectors. The U.S. maintains a significant share due to its concentration of manufacturers and end-users, along with continuous investment in modern casting machinery and simulation capabilities. Emerging markets such as the Middle East & Africa and Latin America show slower growth but represent future opportunities due to ongoing industrialization and infrastructure development.

Market Segmentation and Key Applications

The metal casting market is segmented by casting process types, material types, applications, and vehicle types. High-pressure die casting (HPDC) is considered the fastest-growing process segment, valued for its efficiency, precision, and suitability for mass production of complex parts.

Aluminum holds the largest material share in the market thanks to its properties such as durability, lightweight, and performance benefits in automotive applications. Engine and transmission components, along with alloy wheels, battery housings, and structural assemblies, are major product categories utilizing aluminum castings.

The automotive sector remains the dominant application area, accounting for the largest market share. Growth in this segment is propelled by trends toward electric vehicles (EVs), increased vehicle production volume, and stringent emission standards leading to the adoption of lightweight metal components.

Future Outlook and Challenges

The metal casting industry is expected to continue its upward trajectory in the coming decade owing to technological advancements, growing demand for sustainable materials, and expanding end-use industries worldwide. Precision casting aided by AI, automation, and simulation technologies will further improve product quality and reduce operational waste.

However, challenges such as fluctuating raw material prices, energy-intensive processes, and the need for skilled labor pose potential restraints. Adoption of environmentally friendly production techniques and innovative materials will be crucial for sustainable growth.

In summary, metal casting remains an essential manufacturing process underpinning multiple vital industries. Its evolution through technological integration and increasing market demand is set to drive considerable growth through 2033, with Asia Pacific leading the charge and significant opportunities emerging globally. The market’s versatility and cost-effectiveness ensure that metal casting will remain a cornerstone of industrial manufacturing well into the future.