Introduction to Torque Vectoring Technology

Torque vectoring is an automotive technology that enhances vehicle stability, handling, and cornering performance by autonomously regulating the torque distributed to each wheel or axle. Primarily found in high-performance or all-wheel-drive vehicles, it optimizes power distribution to improve traction, safety, and driving dynamics, especially in challenging conditions such as slippery roads or sharp turns. The technology is applicable across various vehicle types, including passenger cars, commercial vehicles, and off-road vehicles powered by petrol, diesel, CNG, or electric engines.

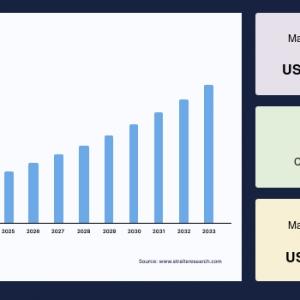

Market Overview and Growth Drivers

The global Torque Vectoring Market was valued at USD 10.02 billion in 2024. It is expected to reach from USD 12.16 billion in 2025 to USD 57.36 billion in 2033, growing at a CAGR of 21.4% over the forecast period (2025-33).

Additionally, stricter global regulations on fuel efficiency and emissions, such as Corporate Average Fuel Economy (CAFE) standards and Euro 6 norms, compel automakers to incorporate torque vectoring systems. These systems contribute to reducing energy losses and optimizing power distribution, thus enhancing fuel economy and helping manufacturers meet emission targets.

Regional Insights

Europe leads the torque vectoring market with the largest share, fueled by the presence of prominent automobile manufacturers like Volkswagen, BMW, Mercedes-Benz, and Audi, who specialize in high-end vehicles equipped with torque vectoring systems. The automotive sector also accounts for more than 7% of the European Union's GDP, reflecting strong support infrastructure and favorable regulations.

Asia-Pacific emerges as the fastest-growing market. Rapid urbanization, industrialization, and economic growth in countries such as China, India, Japan, and South Korea drive demand for torque vectoring systems. These nations are making substantial investments in electric vehicle technology and are adopting stringent emission standards that support the market’s rapid expansion.

Vehicle and Technology Segmentation

The passenger cars segment dominates the market in terms of revenue share. These vehicles, including premium and sports cars, require sophisticated torque vectoring technology to enhance performance and safety. Among propulsion types, all-wheel drive/four-wheel drive (AWD/4WD) systems hold the largest market share due to their superior traction, stability, and ability to distribute torque across all wheels, enhancing vehicle control in diverse driving conditions.

Torque vectoring technology is divided into active and passive systems. Passive torque vectoring, which applies braking force to specific wheels to improve vehicle dynamics, holds the larger market share. It offers a cost-effective solution by utilizing existing braking systems without needing additional hardware. On the other hand, active torque vectoring systems actively redistribute torque via electronically controlled differentials or motors, offering higher precision but at increased complexity and cost.

Clutch actuation types are segmented into hydraulic and electric, with hydraulic clutches dominating the market. Hydraulic systems utilize fluid pressure to engage and disengage clutches, enabling smooth power transfer and gear shifting in torque vectoring applications.

Challenges and Opportunities

Despite its benefits, torque vectoring technology faces obstacles related to high costs and system complexity, limiting its widespread adoption in mass-market vehicles. The systems require advanced components like sensors, controllers, clutches, and motors, which increase manufacturing and maintenance expenses. Additionally, these systems add weight and volume to vehicles, which can impact their aerodynamics and fuel efficiency.

Nevertheless, continuous advancements and innovations, such as the integration of Artificial Intelligence (AI) for adaptive torque management and the development of compact electric drive systems, promise to overcome these challenges. Recent industry developments include the introduction of Lamborghini’s electric crossover concept featuring torque vectoring technology and Hyundai-Kia’s Uni Wheel system designed to save space and energy.

Conclusion

The torque vectoring market is poised for significant growth driven by the electric vehicle revolution, stringent emissions regulations, and increasing demand for vehicle safety and performance. Europe remains the largest market, supported by its strong automotive industry and regulatory framework, while Asia-Pacific offers the highest growth potential. Technical advancements and innovations in torque vectoring systems will continue to enhance vehicle dynamics and fuel efficiency, making torque vectoring an essential component of future automotive design and manufacturing.